DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

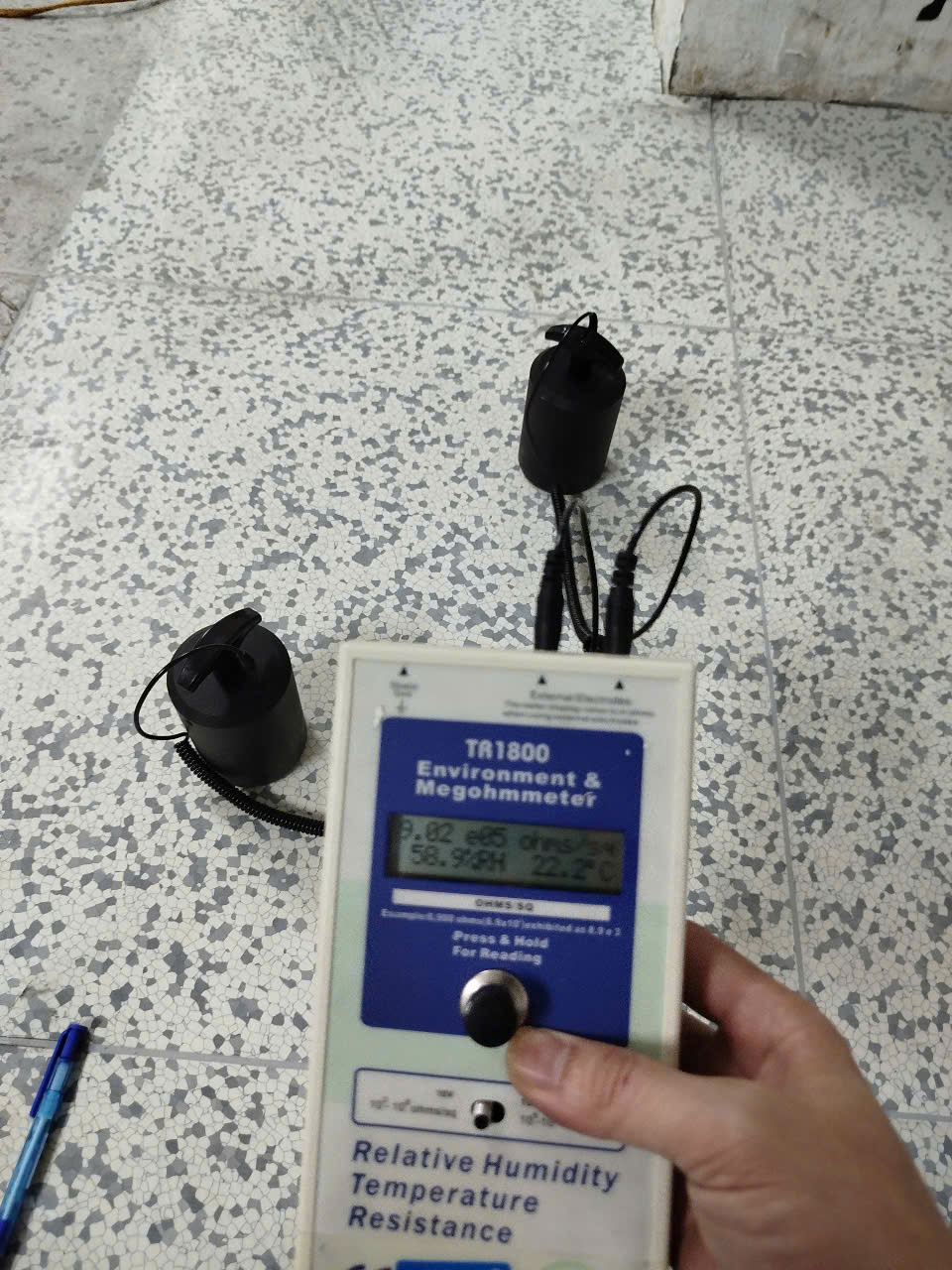

ESD Vinyl Flooring is a durable, static-control flooring solution designed to safely dissipate electrostatic charges, protecting sensitive electronics and equipment in cleanrooms, labs, and industrial environments.

In today’s high-tech industries, controlling electrostatic discharge (ESD) is more important than ever. Sensitive electronic components, medical equipment, and precision devices can be damaged by even the smallest static charge. To address this challenge, many facilities adopt ESD Vinyl Flooring, a durable and cost-effective solution designed to minimize static buildup and safely discharge it to the ground.

This article explores what ESD vinyl flooring is, its features, benefits, applications, and why it has become the preferred choice for cleanrooms, electronics manufacturing, and industrial environments.

ESD vinyl flooring is a specialized type of vinyl flooring engineered to provide electrostatic control. Unlike standard flooring materials, it contains conductive or dissipative layers that allow static electricity to be transferred safely to the ground.

The flooring is typically made of multiple layers, including:

This layered construction makes ESD vinyl flooring not only effective at static control but also highly durable and suitable for heavy-duty industrial use.

👉 Related: Discover our range of ESD Mats for localized workstation static protection.

Both options comply with international ESD standards (ANSI/ESD S20.20, IEC 61340), ensuring safety and reliability.

👉 See also: Cleanroom Swabs for safe contamination control in critical environments.

Installation

Maintenance

👉 For full protection, pair ESD flooring with accessories like ESD Wrist Straps and ESD chairs.

There are different types of ESD flooring materials, including rubber, epoxy, and carpet. However, vinyl flooring stands out due to its:

ESD Vinyl Flooring is an essential solution for industries where static control is critical. By safely dissipating electrostatic charges, it protects sensitive equipment, ensures compliance with international standards, and enhances workplace safety.

From electronics manufacturing to cleanrooms and healthcare, ESD vinyl flooring delivers durability, reliability, and cost efficiency. When combined with other ESD products, it provides a comprehensive defense against electrostatic discharge, ensuring smooth operations and protecting valuable assets.

Investing in high-quality ESD vinyl flooring is not just about compliance—it is about securing the future of your business in today’s technology-driven world.

Cleanroom equipment

Cleanroom equipment

Anti-static

Cleanroom equipment

Cleanroom equipment

Cleanroom equipment

Cleanroom equipment

Cleanroom equipment

Reviews

There are no reviews yet.