DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

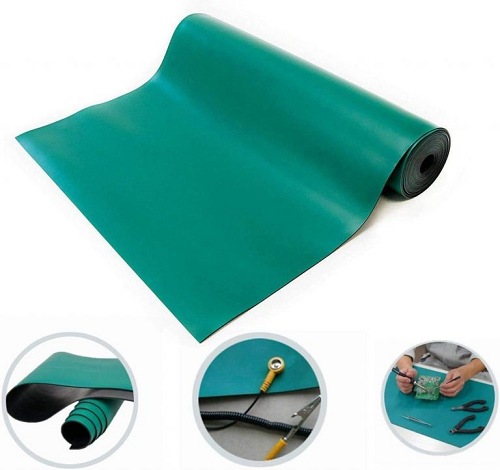

ESD Rubber Mats provide reliable static control, heat resistance, and comfort—ideal for cleanrooms, labs, and electronics manufacturing.

In industries such as electronics, semiconductors, telecommunications, and cleanrooms, even the smallest electrostatic discharge (ESD) can damage sensitive components or disrupt production processes. This is where ESD Rubber Mats come into play. Designed to safely dissipate static electricity, these mats are an essential part of any ESD-safe workstation or flooring system.

This article will explore the benefits, applications, types, and maintenance tips for ESD Rubber Mats, helping you understand why they are a vital investment for static control.

ESD Rubber Mats are specialized anti-static mats made from two-layer or three-layer rubber material. Their primary function is to provide a controlled path for static charges to safely dissipate to ground, preventing harmful static discharge that could damage electronic components or endanger workers.

These mats are commonly placed on workbenches, floors, or assembly stations where sensitive devices are handled.

By grounding static charges, ESD Rubber Mats reduce the risk of damaging delicate microchips, circuit boards, and other electronic parts.

Made from high-quality rubber, these mats are highly resistant to wear and tear, making them suitable for long-term use in demanding industrial environments.

Many ESD rubber mats can withstand soldering sparks, heat exposure, and cleaning chemicals, ensuring both safety and easy maintenance.

When used on workbenches or floors, these mats provide a cushioned surface, reducing operator fatigue during long working hours.

Available in rolls, pre-cut sheets, or custom sizes, ESD mats can be installed in different work areas depending on requirements.

Electronics Manufacturing

ESD mats are essential in PCB assembly, semiconductor production, and mobile device manufacturing, where static protection is critical.

Cleanrooms and Laboratories

In clean environments, ESD rubber mats help maintain static-free conditions while also resisting particle buildup.

Repair and Testing Stations

Technicians use ESD mats to protect devices during maintenance, soldering, or quality control inspections.

Industrial Workstations

Factories handling sensitive components or high-tech equipment rely on ESD flooring solutions to ensure safe operations.

While ESD Vinyl Flooring (read more about ESD Vinyl Flooring) is a great solution for covering larger areas, rubber mats offer higher durability, better heat resistance, and long-term cost efficiency. They are especially preferred in soldering and rework stations where sparks and heat are frequent.

In any environment where static-sensitive devices are manufactured, assembled, or repaired, ESD Rubber Mats are indispensable. They not only protect valuable electronic components from electrostatic damage but also improve workplace comfort and safety.

By investing in high-quality ESD mats and combining them with other ESD-safe products such as ESD Shoes (learn more about ESD Shoes here) and wrist straps, companies can create a comprehensive static control program that ensures efficiency, safety, and compliance with international standards.

Whether you’re setting up a small workstation or managing a large-scale electronics facility, ESD Rubber Mats are a cost-effective and reliable solution to protect both your employees and your products.

Anti-Static Mats

Anti-Static Mats

Anti-Static Mats

Anti-Static Mats

Anti-Static Mats

Reviews

There are no reviews yet.