DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

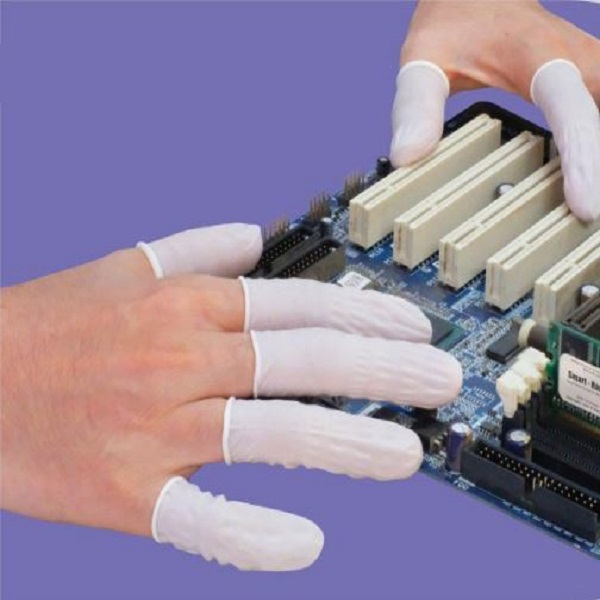

Fingerstalls are protective coverings worn on individual fingers to prevent contamination, static discharge, and damage when handling sensitive components. They are ideal for use in electronics, cleanrooms, laboratories, and precision assembly.

In precision industries such as electronics, semiconductors, and medical manufacturing, the smallest contaminants or electrostatic discharges can cause serious defects. This is why fingerstalls play an essential role in providing both personal protection and product safety. Unlike traditional gloves, fingerstalls cover only the fingers, giving workers dexterity while ensuring cleanliness, static protection, and hygiene.

This article will explore the definition, features, benefits, applications, and buying considerations for fingerstalls, making it easier for businesses to choose the right type for their production needs.

A fingerstall is a protective covering worn over individual fingers, commonly made of latex, rubber, or anti-static materials. They are widely used in industries where:

Fingerstalls are available in various forms, including:

Fingerstalls are designed to fit snugly on each finger, ensuring workers can handle tiny parts without losing precision. They may have textured tips for better grip and are usually rolled for easy application.

To maximize comfort, fingerstalls come in multiple sizes (small, medium, large). The correct fit prevents discomfort during long shifts.

Fingerstalls prevent oils, sweat, and dirt from contaminating delicate components, especially in electronics and optical devices.

In industries where static electricity can damage products, ESD fingerstalls help neutralize static charges, providing safe handling of printed circuit boards (PCBs), microchips, and sensors.

Unlike full gloves, fingerstalls allow workers to keep most of their hand uncovered, improving breathability and flexibility.

Since they only cover the fingers, fingerstalls often cost less than full ESD gloves while still providing essential protection.

Fingerstalls are widely used in:

For example, when handling printed circuit boards (PCBs), using fingerstalls alongside ESD gloves can provide maximum safety against both static electricity and contamination.

While both fingerstalls and ESD gloves serve similar functions, there are distinct differences:

Some companies use fingerstalls for short tasks requiring dexterity and switch to gloves for longer operations.

When selecting fingerstalls, consider the following:

For comprehensive protection in a cleanroom environment, fingerstalls can be combined with ESD wrist straps to ensure full grounding of the operator.

Fingerstalls are an essential protective product for industries where precision, cleanliness, and static control are critical. Their ability to provide targeted protection while maintaining dexterity makes them a preferred choice in electronics manufacturing, cleanrooms, laboratories, and more.

By understanding their features, applications, and advantages, businesses can make informed decisions when choosing the right fingerstall type. For the best results, they should be used in combination with other ESD-safe equipment, ensuring a comprehensive static-control system.

Rubber Finger Cots

Rubber Finger Cots

Rubber Finger Cots

Reviews

There are no reviews yet.