DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

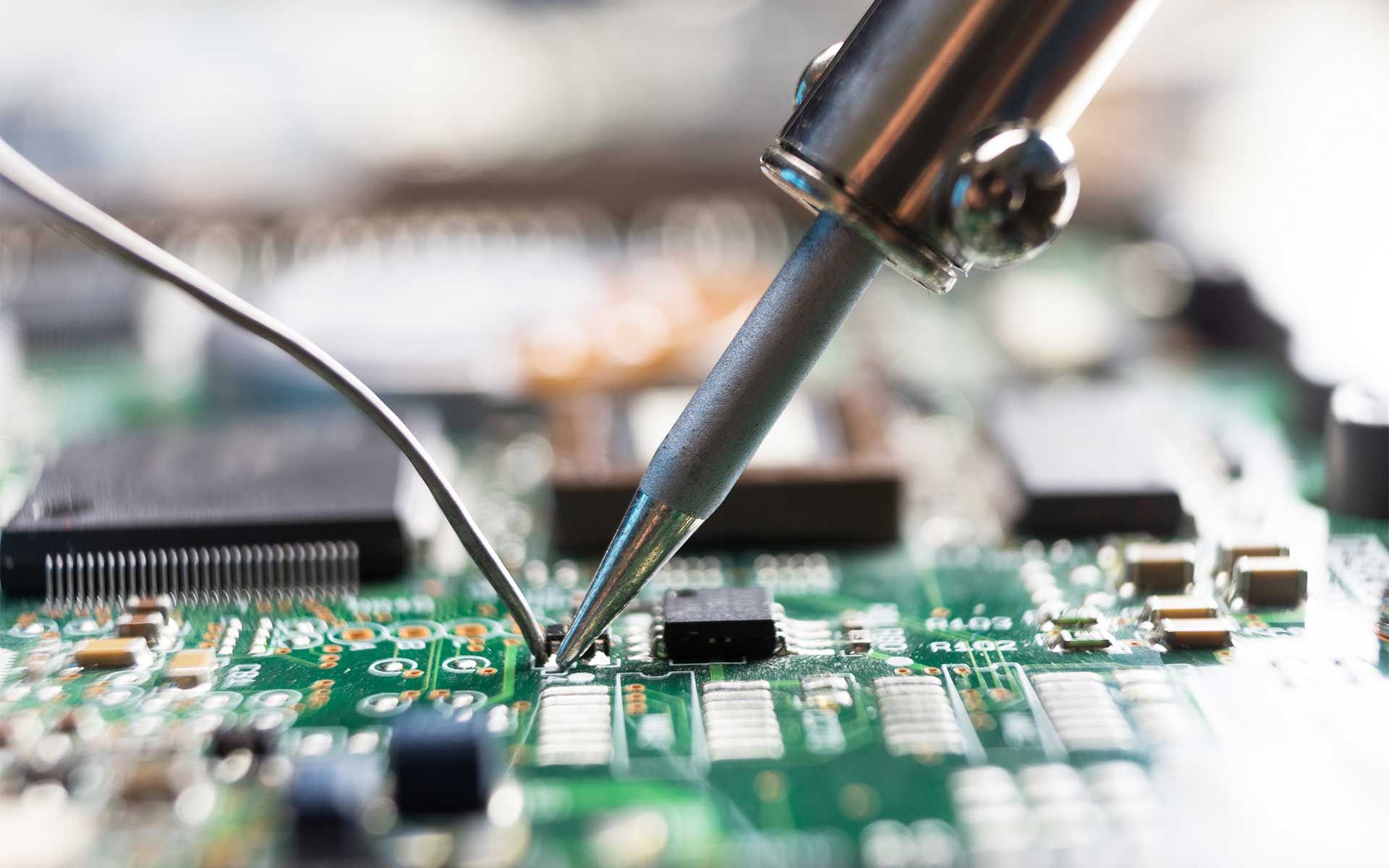

Solder Roll provide a continuous supply of high-quality solder wire, ensuring strong, conductive, and durable connections for electronics, electrical, and industrial applications. Ideal for PCB assembly, repairs, and precision soldering.

In the world of electronics manufacturing, repair, and assembly, one material stands out as indispensable: the solder roll. Whether in large-scale industrial production lines or small workshops, solder rolls play a vital role in creating secure electrical connections and ensuring reliable circuit performance. Known for their convenience and efficiency, solder rolls provide engineers, technicians, and hobbyists with a consistent supply of soldering material for a wide range of applications.

This article explores what solder rolls are, the different types available, their benefits, applications, and why choosing a high-quality solder roll is essential for achieving the best soldering results.

A solder roll is a coil of solder wire wound onto a spool, designed for convenient storage and continuous use. The solder itself is a fusible metal alloy that, when heated, melts and bonds two metallic surfaces together. This process ensures both mechanical strength and electrical conductivity, which are crucial in electronic devices and electrical systems.

👉 Related: Learn more about our Solder Wire options for precision soldering.

Flux is a chemical agent integrated into the solder wire’s core. Its purpose is to remove oxidation from metal surfaces and improve wetting during soldering. Types of flux cores include:

Solder rolls are versatile and widely used across industries. Common applications include:

👉 See also: ESD Wrist Strap for safe and static-free electronics work.

👉 For clean handling and contamination-free assembly, check out our Huby Swabs.

Conclusion

Solder rolls are an essential material in electronics, electrical engineering, and manufacturing. Offering convenience, consistency, and performance, they are the preferred choice for professionals and hobbyists alike. From delicate PCB assembly to heavy-duty wiring, the right solder roll ensures durable, conductive, and reliable connections.

By choosing high-quality solder rolls, industries and individuals can enhance productivity, reduce errors, and achieve superior soldering results. In today’s fast-paced world of electronics, having a dependable solder roll is not just an option—it’s a necessity.

Solder Wire

Solder Wire

Reviews

There are no reviews yet.