DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

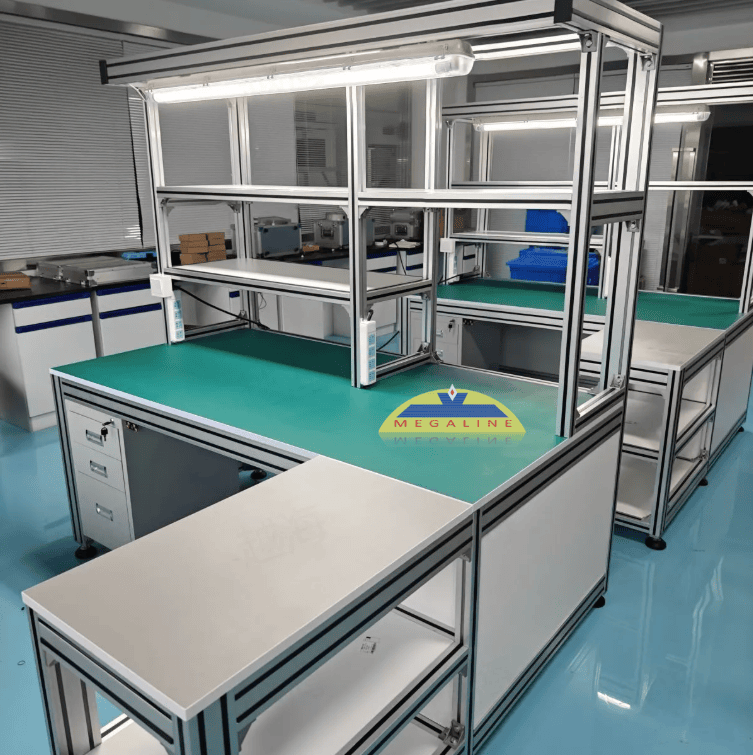

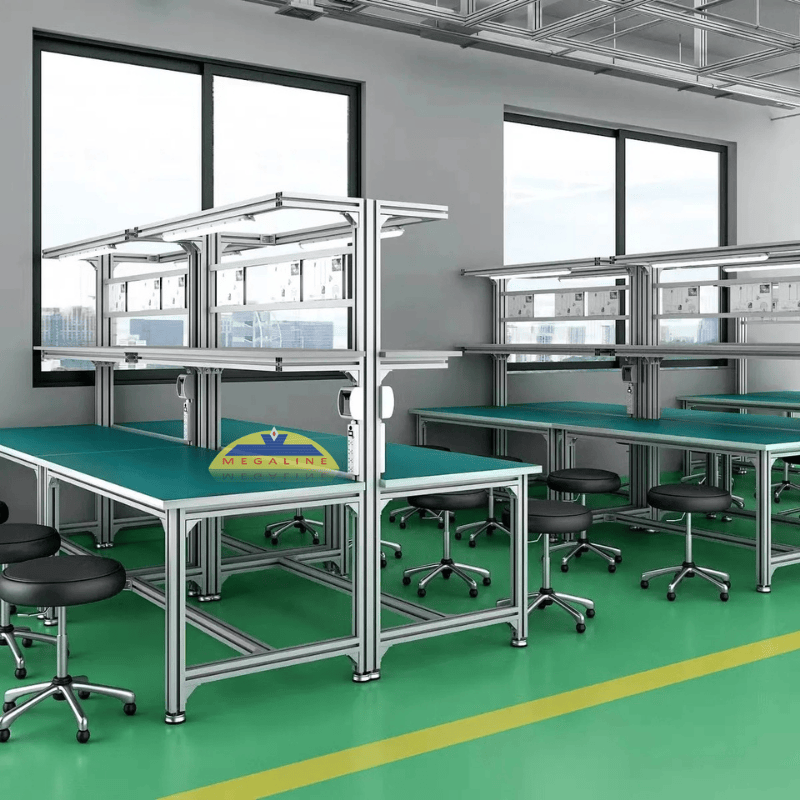

Anti-static workbenches are a specialized solution that helps protect electronic components and sensitive equipment from damage caused by static electricity, ensuring a safe and efficient working environment.

The anti-static workbench is an essential piece of equipment in industries that require strict electrostatic control, especially in the production of electronic components, semiconductors, pharmaceuticals, and healthcare. With its ability to minimize the risk of damage caused by electrostatic discharge (ESD), the anti-static workbench helps protect equipment, products, and workers alike.

The anti-static workbench is specially designed with components that dissipate and control static electricity. Its typical structure includes:

Anti-static tabletop: Made from ESD (Electrostatic Discharge) materials that can quickly neutralize static charges, preventing harmful discharges.

Sturdy frame: Usually constructed from powder-coated steel or stainless steel, offering high durability and load-bearing capacity.

ESD rubber mat: Placed on the tabletop to enhance anti-static performance and protect sensitive components from scratches.

Grounding wire: Connects the bench to the grounding system, ensuring that excess static charges are safely discharged without affecting devices or operators.

Drawers and accessory shelves: Integrated for added convenience, helping to keep the workspace organized and efficient.

Using an anti-static workbench offers numerous significant advantages, especially in production environments that require strict electrostatic control:

Protects electronic components and devices: Prevents electrostatic discharge (ESD), minimizing damage to sensitive components.

Ensures worker safety: Reduces the risk of mild electric shocks from accumulated static electricity, creating a safer working environment.

Boosts productivity: By minimizing the risk of damage, work processes run more smoothly, improving overall production efficiency.

Meets industry standards: Complies with strict requirements in industries such as electronics, healthcare, and pharmaceuticals.

Anti-static workbenches are widely used across various industries, including:

Electronics industry: Used in the assembly, inspection, and repair of electronic components.

Semiconductor industry: Protects microchips and semiconductor devices from electrostatic discharge.

Medical and pharmaceutical industries: Used in cleanrooms to maintain an environment free from static interference.

Aerospace and defense sectors: Applied in the manufacturing and maintenance of aerospace and military equipment that requires high precision.

When selecting an anti-static workbench, several important factors should be considered:

Work surface material: Prioritize durable materials with high anti-static performance.

Load capacity: Ensure the bench can support the appropriate weight for your tasks.

Integrated grounding system: Critical for effectively discharging static electricity.

Workbench size: Should match the workspace layout and usage needs.

Flexible design: Adjustable height, optional drawers, or shelving to meet specific requirements.

Related Products:

To ensure optimal performance and longevity of the ESD workbench, it is essential to follow these maintenance and usage tips:

Regular cleaning: Wipe the work surface with a specialized ESD-safe cleaning solution to maintain anti-static performance.

Check the grounding system: Periodically inspect and maintain the grounding connection to ensure reliable static discharge control.

Avoid insulating materials on the surface: Materials such as plastic or rubber that are non-conductive can interfere with the ESD function.

Use additional ESD accessories: Combine with ESD mats, grounding wrist straps, or other accessories to enhance protection.

Depending on your workspace, production requirements, or industry standards, you can customize the length, width, and height of the workbench to ensure a perfect fit. Additional features such as tool racks, drawers, and lighting systems can also be installed upon request, helping optimize workspace and improve productivity.

An ESD workbench is an essential solution in modern industries, providing protection for devices, products, and personnel from electrostatic discharge (ESD) risks. Choosing the right bench and maintaining it properly ensures high working efficiency and long service life. If you’re in search of a quality ESD workbench, consider the above criteria to make the best choice.

Contact information:

Hotline: 0934023546

Head office: No. 3, Sunrise E, The Manor Central Park urban area, Nguyen Xien street, Dai Kim ward, Hoang Mai district, Hanoi city

Website: megaline.com.vn – Cleanroom and industrial equipment

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Reviews

There are no reviews yet.