DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

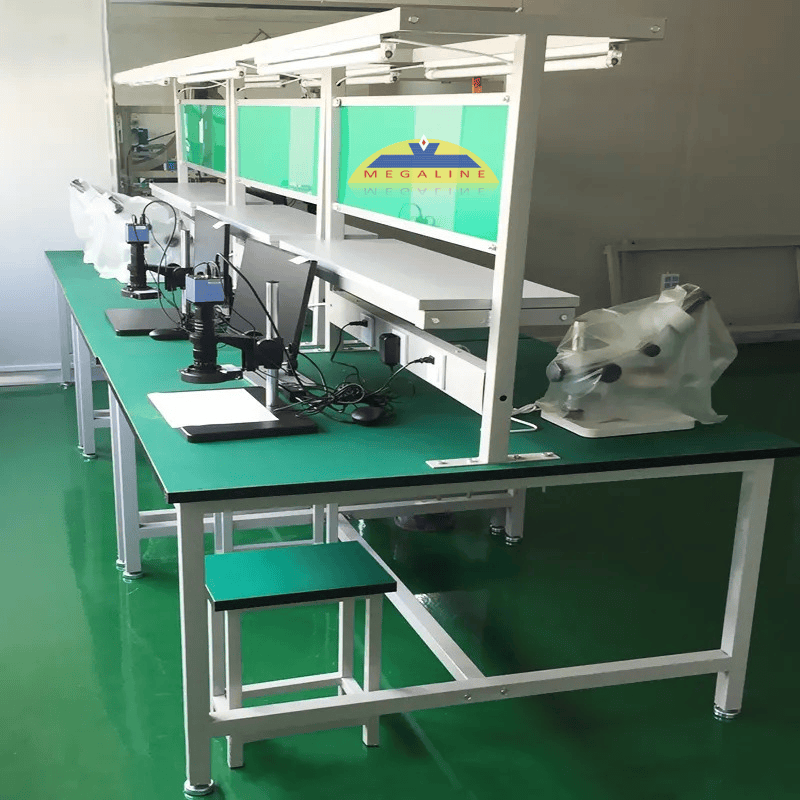

A cleanroom workbench is a specialized piece of equipment designed to maintain a clean working environment by controlling dust and static electricity, meeting the standards required in industries such as electronics, pharmaceuticals, and semiconductors.

Cleanroom workbenches are indispensable equipment in production environments requiring high levels of cleanliness, such as the pharmaceutical, electronics, semiconductor, food, and healthcare industries. They are specifically designed to ensure no dust generation, ease of cleaning, and compliance with stringent cleanroom standards such as ISO 14644-1 or GMP.

Cleanroom workbenches not only optimize workflow but also protect products from contaminants, helping to maintain the highest quality during the production process.

Cleanroom workbenches have a simple structure but are made from special materials to ensure durability and resistance to contamination. The main components include:

There are many types of cleanroom workbenches, suitable for various usage requirements:

Cleanroom workbenches are widely used in many fields:

Cleanroom workbenches help to effectively control dust, bacteria, and contaminants, thereby ensuring product quality and production processes meet the highest standards.

Workbenches help create a scientific workspace, allowing workers and technicians to operate easily and increasing production output.

High-quality manufacturing materials such as 304, 316 stainless steel or aluminum profiles give the workbenches a long lifespan, reduce damage, and save maintenance and replacement costs.

With many different types of workbenches, users can choose the product that best suits their production environment.

Related products:

When choosing a cleanroom workbench, consider the following factors:

We provide installation and custom fabrication services for cleanroom workbenches according to the specific dimensions and requirements of customers. Our experienced technical team will advise, design, and manufacture workbenches suitable for your workspace, ensuring the highest quality and compliance with strict cleanroom standards.

Cleanroom workbenches are essential equipment in production environments with stringent standards. Choosing the right type of workbench not only improves work efficiency but also ensures product quality and user safety. To have a professional and standardized workspace, investing in cleanroom workbenches is a wise decision for businesses.

Contact information:

Hotline: 0934023546

Head office: No. 3, Sunrise E, The Manor Central Park urban area, Nguyen Xien street, Dai Kim ward, Hoang Mai district, Hanoi city

Website: megaline.com.vn – Cleanroom and industrial equipment

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Reviews

There are no reviews yet.