DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

DA NANG: 126 Dien Bien Phu, Thanh Khe, Da Nang

HO CHI MINH: 140 Vo Van Kiet, District 1, Ho Chi Minh

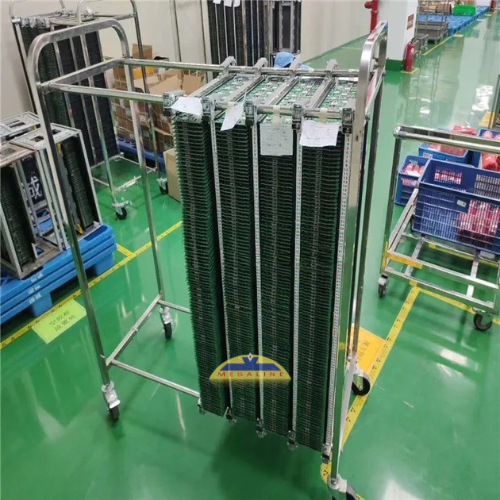

PCB trolley is a specialized device designed to safely and efficiently transport and organize electronic circuit boards during the manufacturing process. With a sturdy construction, anti-static capability, and various size options, the PCB trolley optimizes the component transportation workflow within the factory.

In the electronics industry, the transportation of Printed Circuit Boards (PCBs) is a crucial step that requires precision, safety, and efficiency. PCB trolleys are specialized equipment that helps optimize this process, ensuring that circuit boards are moved safely without damage from impact, electrostatic discharge, or environmental contamination.

PCB trolleys not only save time and costs but also enhance production efficiency in electronic component assembly plants. With the continuous development of technology, PCB trolley lines are increasingly being improved with many modern features, meeting the stringent demands of the industry.

The frame of a PCB trolley is usually made of aluminum alloy, stainless steel, or anti-static plastic (ESD – Electrostatic Discharge), ensuring high durability and resistance to harsh working environments.

Because PCBs are very sensitive to static electricity, trolleys are often designed with anti-static capabilities thanks to ESD materials, helping to protect electronic components from damaging electrostatic discharge.

Thanks to a specialized design with secure storage slots, the trolley helps protect circuit boards from impact, scratches, or contamination during transportation.

Using trolleys makes it easier to move a large number of circuit boards at once, thereby speeding up production and reducing manual labor.

With anti-static capabilities, the trolley helps protect electronic components from the risk of electrostatic discharge, minimizing product defects and thereby improving production quality.

Using trolleys helps reduce the incidence of damaged circuit boards, thereby reducing replacement and repair costs, while optimizing the workflow in the factory.

4.2. Adjustable Size PCB Trolleys

4.3. Anti-Static (ESD) PCB Trolleys

See more:

PCB trolleys are widely used in many fields, especially electronics manufacturing:

PCB trolleys are an indispensable solution in the electronics industry, helping to protect circuit boards, increase work efficiency, and reduce production costs. Choosing the right type of trolley that suits your needs will help businesses optimize production processes, ensure product quality, and improve operational efficiency.

When buying a PCB trolley, pay attention to material quality, anti-static capabilities, load capacity, and flexibility to ensure it meets your business’s production requirements. Investing in high-quality trolleys will bring long-term benefits, helping your business grow sustainably in the electronics industry.

Megaline is a reputable supplier specializing in various types of industrial trolleys for many manufacturing, warehousing, logistics, and workshop sectors. With a diverse range of models and load capacities from light to heavy-duty, Megaline’s products are designed to be sturdy and durable, helping to optimize the goods transportation process, reduce labor, and increase work efficiency. Committed to providing safe, efficient, and cost-effective solutions, Megaline is always ready to meet the needs of businesses with high-quality products and professional services.

Contact information:

Hotline: 0934023546

Head office: No. 3, Sunrise E, The Manor Central Park urban area, Nguyen Xien street, Dai Kim ward, Hoang Mai district, Hanoi city

Website: megaline.com.vn – Cleanroom and industrial equipment

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Assembly Processing

Reviews

There are no reviews yet.